Maviro has expertise and technology to clean tanks of all sizes and volumes with virtually any stored material or contaminant including crude/fuel, storage, process tanks, basins, rail-cars, barges and other vessels. Maviro cleans to API 653 Inspection Standards.

Maviro expert tank cleaning methods utilize the latest equipment, processes and techniques available for specialized tank cleaning.

Vapor Controls and De-gassing Applications

Sludge De-Watering Methods

Productivity with Reduced Exposure

Maviro provides certified confined space rescue teams and offers light mechanical services for piping/flanges, blinding and man-way removal as projects require.

Maviro's safe, efficient and cost effective tank cleaning processes decrease time on site, and can reduce personnel exposure utilizing our non-entry, remote-control methods.

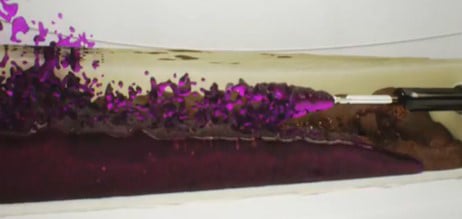

Helps control sludge volume build ups to meet operational needs and increase product purity. Spill free operation

No tank Entry. Fluidize and extracts waste material via 8 inch valves. Used on tanks with more than 6ft of sludge

3-way directional valves to increase coverage. Closed loop system removes material for centrifuge and sludge-dewatering

DIFFERENCE

DIFFERENCEMaviro delivers safe and proven solutions for a variety of specialty industrial services needs to companies across North America.

Understand the problem - Identify a solution , pair with well trained reliable people with the newest technologies results in a Safe efficient project result.

Safety Comes First. Detailed SWP's

Environmental Compliance. Waste minimization and recycling

Project Management. Data Collection , hands on senior team

Measured Performance. Predictable Results.

Integrity and Reputation to find the safest and cost effective solution.

Innovative Options. Thinking outside of the box. Embracing Technology.

Maintenance tool that helps control sludge volume build-ups while in service.